CAVAGNA RENATO

CONTRACT METAL TURNING

Mechanical excellence, continuous innovation and global vision

Cavagna Renato has been a benchmark in contract CNC turning in Italy for over sixty years. Our precision machining is done to customer drawings so as to ensure quality, reliability and on-time delivery.

Thanks to a modern machine park and a specialised team, we are able to produce CNC turned parts from steel, stainless steel, super alloys, brass, aluminium, copper, bronze, plastics and special alloys, and to meet the needs of the most demanding sectors, such as automotive, plumbing, medical, defence, firearms, pneumatics, aerospace, valves, hydraulics, agriculture, earthmoving and furniture-design.

PRODUCTION

Experience and technology

for ever more advanced processing

We collaborate with our customers from the development phase, offering technical advice, rapid prototyping and optimisation for manufacturability.

We offer a complete and customised service from precision turning to surface and heat treatment to assembly.

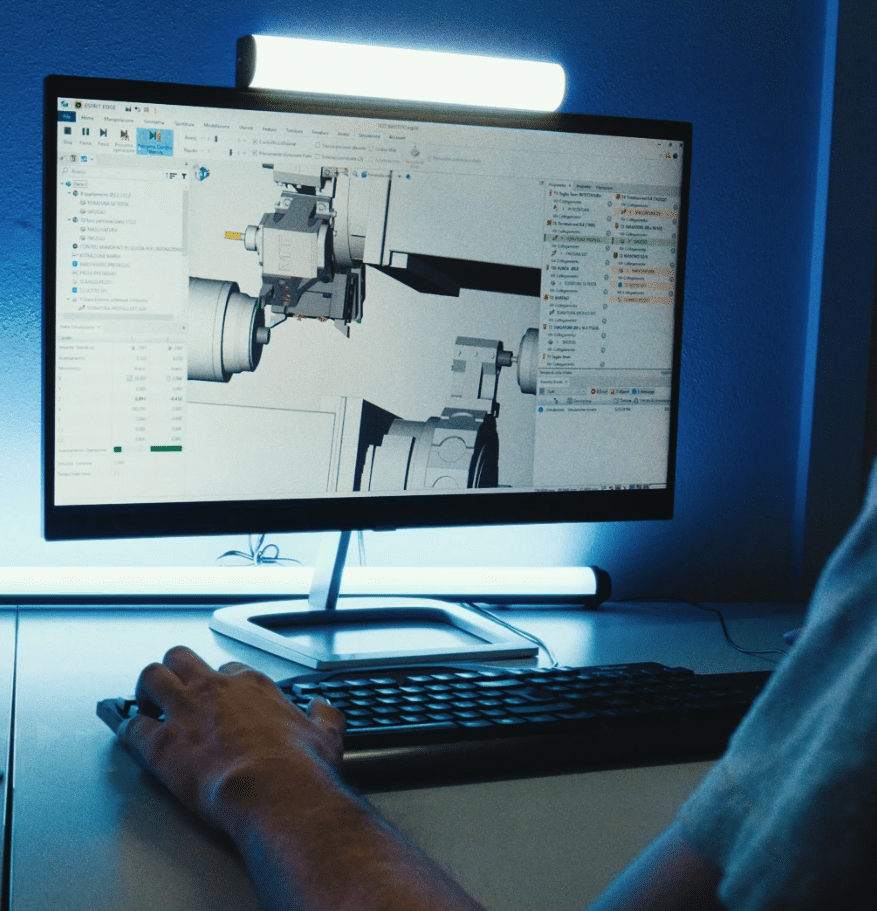

CNC lathes, loading and unloading robots, 3D printing systems and CAD/CAM systems allow us to carry out complex machining with maximum efficiency.

OUR NUMBERS

Our performance in figures

MORE THAN

2,000

ORDERS PROCESSED

PER YEAR

45

SPECIALISED

EMPLOYEES

15

COUNTRIES SERVED

WORLDWIDE

MORE THAN

60

YEARS OF EXPERIENCE

IN THE INDUSTRY

These figures testify to our ability to combine experience, reliability and innovation, and position us as an international benchmark for the manufacture of precision components using CNC lathes.

SETTORI DI PRODUZIONE

Advanced solutions

for major industries

The reliability of our CNC lathes is proven by hard facts: high production capacity, an ever-expanding fleet of machines, dozens of specialised operators and active customers in several countries.

INNOVATION AND VALUES

A professional team, facilities, quality and sustainability

are the pillars of our production

FACILITIES AND TECHNOLOGY

Technology and innovation for quality

Discover our latest generation machinery: CNC lathes and specialised software to ensure efficient and consistent precision components.

QUALITY

Certified quality and advanced metrological control

Reliability and repeatability at every stage: from our integrated quality system to dimensional checks and full traceability, we meet the most stringent of standards.

SUSTAINABILITY

Sustainability and innovation for responsible development

Our commitment to the environment and people is tangible. It encompasses energy efficiency, waste reduction, staff training, and being involved in and creating value for the region, with a future-oriented corporate vision.

Would you like to receive more information?