FACILITIES AND TECHNOLOGY

CNC TURNING EQUIPMENT

Our workshop is equipped with a constantly updated fleet of machines, which can respond to small, medium and large series orders. We continuously invest in new technologies to ensure efficiency, flexibility and consistent quality.

We have single and dual-spindle CNC lathes and sliding headstock lathes, which are ideal for the production of complex, close-tolerance turned parts. The combination of these facilities allows us to produce customised components, optimise cycle times and reduce waste.

AUTOMATION AND ROBOTICS

Automation systems for automatic loading and unloading robots combined with CNC machines reduce time, optimise cycles and maintain high quality even in continuous production.

SPECIALISED SOFTWARE

We use state-of-the-art CAD/CAM software for the 3D modelling and 3D printing of prototypes that allow us to simulate parts, CNC programming and measuring instrument programming, so we can validate each cycle before production.

LASER MARKERS

We have laser markers for traceability.

ULTRASONIC CLEANING

We have an IFP metal washer with automatic loading and unloading to clean parts.

PACKAGING SYSTEMS

Customised packaging solutions according to customer requirements to protect components and optimise logistics.

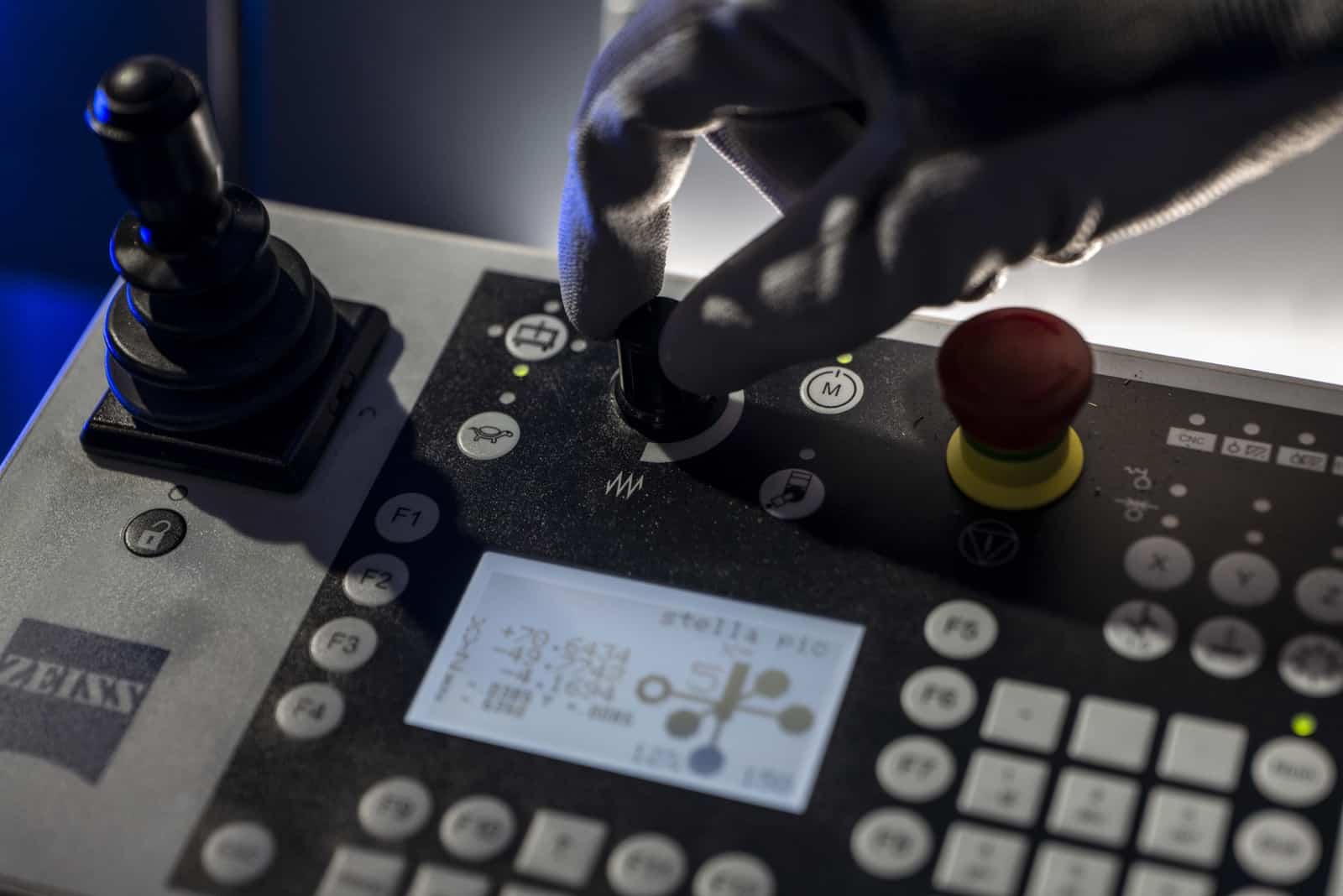

METROLOGICAL FACILITIES

Cavagna Renato has latest generation metrology equipment to ensure the conformity of each component. This includes air-conditioned rooms, three-dimensional measuring machines, profilometers, roughness gauges and optical instruments for accurate testing. These systems allow us to constantly monitor production and ensure tight tolerances and full traceability.